The Most Common Wiring Systems

Electrical wiring involves installing wires by the professionals from Ampi Electric Inc. that distribute power to various appliances and fixtures in a structured manner. It also ensures that the power supply is uninterrupted. The most common type of house electrical wiring is non-metallic (NM) cable. It has a hot, neutral, and ground wire with a plastic sheathing. We offer free estimates on all of our services, so you can be sure you’re getting the best value for your money. Call Us Today in order to get started on your next project!

Conduit Wiring

In this system of wiring, all wires and cables are passed through iron or PVC pipes. The purpose behind this is to safeguard them against unpleasant consequences like weather conditions, physical breakdown, and fire dangers. It also provides an extra level of protection to the cables and wires from rodents and other environmental factors.

This type of wiring is usually used in large industrial or commercial buildings. There are different types of conduit, and each one has its own rules for installation and use. For example, some types of conduit can only be used in wet or corrosive locations, while others must be used in dry areas.

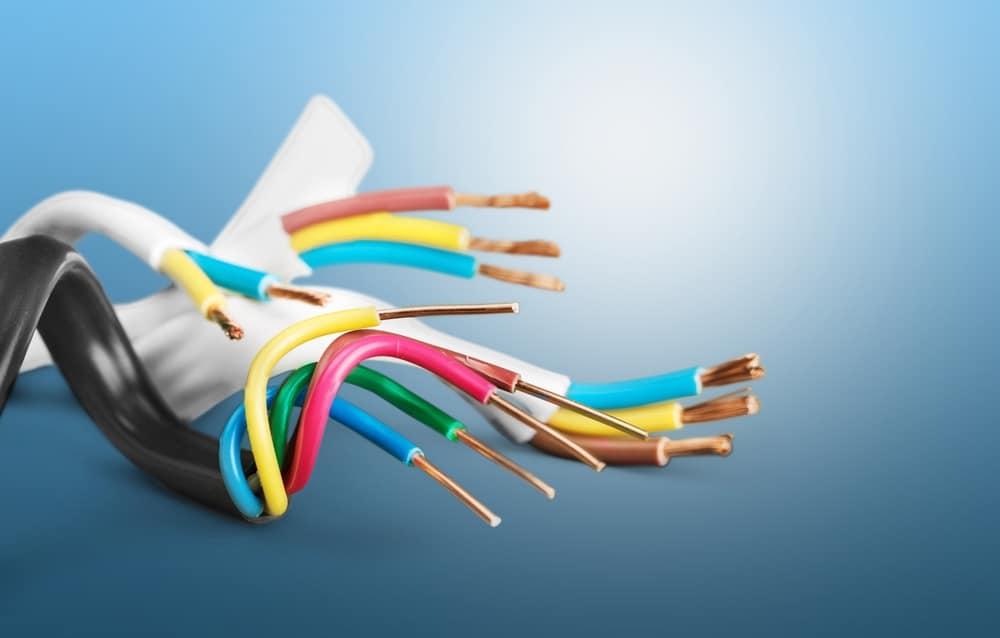

Conductors in conduit are typically grouped into different color categories to indicate their functions and help prevent accidents and injuries. These color codes are as follows:

BLACK (OR RED) = HOT. These wires carry current to the device they connect to, which could be a switch, receptacle, or light fixture. WHITE = NEUTRAL. These wires carry current to other devices in the circuit, completing the circuit. BARE (OR GREEN) = GROUND. These wires provide a path for electricity to return back to its source, the electrical panel, in the event of a fault.

This method of wiring has been in use since the 19th century and is still widely used today. It employs VIR-insulated conductors covered with a sheath that protects them from mechanical damage and humidity. The sheath is also grounded to avoid leakage current. It is a very reliable and durable method of wiring, but it can be costly.

Despite the many benefits of this type of wiring, there are some disadvantages to using it in residential homes and other small buildings. For one, conduit wiring is a relatively complex and expensive process to install. It can also pose a safety risk if not installed properly.

Another issue with conduit wiring is that it can make it difficult to upgrade or repair existing wiring without tearing down the entire wall or ceiling. While there are ways to minimize this problem, it is still an important concern for people who live in older homes and want to upgrade their electrical systems.

Casing & Capping Wiring

Casing & capping wiring is an electrical system that uses PVC insulated wires enclosed in plastic casings and sealed with a cap. This is a popular method for household wiring, wire distribution, protection of other wiring systems and offices with low voltage use. The casing is commonly a rectangular strip, and the channel and cap are usually grey or white.

The installation procedure for this kind of wiring is simple. First, the bottom portion is fastened to the walls. Then, the wiring is fed downward and the cover is pressed against the base. The design can be either press and fit or sliding, depending on the material. PVC is hard to press, so sliding designs are more common. It’s important to note that the wires should be matched with their proper colors so that the wiring is safe to touch.

For instance, black wires indicate hot wires that carry current to the device they connect to. This could be a switch, receptacle or light fixture. While white wires indicate neutral wires that carry current back to the panel. Finally, bare or green wires are grounding wires that conduct electricity back to the panel in the event of an electrical fault.

Besides being quick to install, this type of wiring is also easy to modify, and it can be easily adapted to any home. Another benefit of this system is that it can be used in outdoor areas, such as garages and sheds.

This wiring method has been in use for years, but it’s becoming less popular as conduit and sheathed wiring systems become more popular. It’s a good choice for homes that have a woody appearance or want to avoid the look of exposed cables. The wiring is laid over batten, a long strip of wood, and brass link clips hold the wires together.

Casing & capping wiring sets are available in various trunk sizes and colors, making them a versatile choice for many projects. They’re also ideal for covering unconcealed wiring in residential and commercial settings. Also known as casing patti in India, these wire covers are a great way to hide your wiring while ensuring that it is safe for you and your family to touch.

TRS Wiring

TRS wiring (Tip, Ring, Sleeve) is a wire that features three conductors: the tip, ring, and sleeve. Its conductors are covered in tough rubber that can withstand mechanical damage. It’s also moisture and chemical-proof. It’s often used in audio cables, connecting microphones and instruments to mixers and other devices. TRS cables are available in various sizes, and can be used with either mono or stereo signals.

The sleeve conductor connects the tip and the ring. The sleeve can carry a left signal or a right signal, depending on the connection type of the cable. In balanced TRS cable, the sleeve connects to a third conductor that provides a common pathway for both the left and the right audio signals. In unbalanced TRS cable, the sleeve is connected to a second conductor that provides a ground connection for both the left and the right audio signals.

TS cables are typically used with mono-unbalanced signals. They can be plugged into devices with TRS inputs, or can be converted to use with TS connectors with adapters. Like TRS cables, TS cables can come in different plug sizes, but the most common in pro-audio is the 1/4’’ jack. This jack has a pointed metal bit on one end called the tip, and a long metal shaft on the other called the sleeve. The two parts are separated by a black band that acts as an insulator to prevent them from shorting together.

There are many types of jacks, and they have different purposes in audio applications. The 3.5mm TRS jack is commonly used to transmit stereo audio signals, but can also be used for mono, balanced, and unbalanced signals. In most cases, a 3.5mm TRS cable is used to connect an instrument or microphone to an auxiliary input on a device.

Although the 3.5mm TRS connector is designed to handle balanced signals, it’s not compatible with all audio equipment. Some 3.5mm TRS connectors have two conductors, and will only function as an unbalanced signal in the absence of a third conductor. Check your equipment’s specifications to ensure that it supports balanced connections. It’s also important to make sure the jack connector is completely inserted, as loose or partially inserted connections can cause interference and other issues.

Catenary Wiring

Catenary wiring is one of the most common systems for overhead wires, especially when it comes to electric trains. The name “catenary” comes from the Latin word for chain, as these overhead lines look very much like a chain. They are usually made from copper or aluminum wire strands. This system has the advantage of keeping high-voltage train power up away from people on the ground, which is a major safety benefit. It is also less expensive than underground conduits. However, it is not as flexible and it requires lots of maintenance to prevent rust and corrosion on the support structures, such as steel poles.

This system consists of a contact wire, auxiliary messenger wires, droppers, and masts with insulators. The contact wire is the main cable that carries electricity from the overhead wires to the train’s roof-mounted power pick-up (pantograph). It is normally around 107 square meters of cadmium copper or aluminum wire. The auxiliary messenger wires (or “droppers”) are attached to the contact wire at regular intervals, which can vary in length depending on the type of single-catenary construction. The droppers may be curved, following the curve of a wire not under tension, or straight, connecting to the contact wire at a fixed point.

The masts with insulators help to keep the catenary wires in place, along with the support structures. They are also used to separate the power distribution into electrical sections, which is necessary to ensure that only the power needed for a specific train section is supplied to it. This is particularly important for long-distance trains.

The power for this system is fed from a traction power substation, and the wires are connected to it using sheath cables. These cables are typically tough sheathed cable systems, such as those with cab tire, PVC, or lead sheaths. These sheaths protect the cable from mechanical damage and the weather. They are also very important for preventing the sheath from becoming energized and potentially dangerous. In addition, these sheaths provide the ability to upgrade and add more conductor pairs to a single cable without having to build a new mast.

Electrical wiring involves installing wires by the professionals from Ampi Electric Inc. that distribute power to various appliances and fixtures in a structured manner. It also ensures that the power supply is uninterrupted. The most common type of house electrical wiring is non-metallic (NM) cable. It has a hot, neutral, and ground wire with a plastic…

Recent Posts

- Abilene Electricians: Setting the Standard for Excellence in Electrical Services

- Abilene Electricians: Setting the Standard for Excellence in Electrical Services

- Eco-Friendly Power: How Solar Panels Are Changing the Game in NT

- Eco-Friendly Power: How Solar Panels Are Changing the Game in NT

- Driving the Future: Exploring the Advancements in Electric EV Technology